FRP Pultruded Profiles

Everlast Pultruded Fiberglass Sections provide a unique and unmatched combination of corrosion resistivity, high strength, thermal & electrical non-conductivity, dimensional stability and light weight sections providing virtually maintenance free services in most harsh industrial environments where traditional materials like steel, aluminium or wooden have failed to provide all the above properties.

These FRP sections are widely used as a better alternative to stainless steel and other expensive components. Compared to these materials, the manufacture of Everlast pultruded FRP products produces fewer air and water emissions, consumes less energy and emits less greenhouse gas, leading to both a reduced environmental impact and a lower carbon footprint.

Everlast FRP composite products have high resistance to rot and corrosion, a longer and more economical service life and require less frequent energy-intensive maintenance and replacement. These inherent advantages lead to superior overall sustainability for our FRP products.

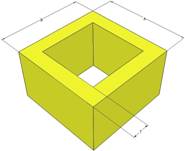

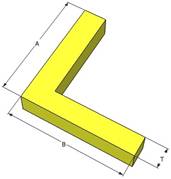

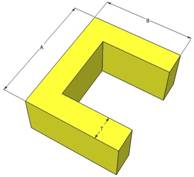

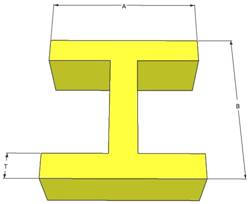

Product Information & Corresponding pictures

Everlast FRP Pultruded Sections include Angles, Channels, I-Beams, Wide flange beams, Round, Rectangular & Square Tubes, Round and Square Bars, Flat Sheets, Concrete embedment angles, etc.

Everlast FRP Pultruded Sections are manufactured using highest quality materials under stringent quality check and testing norms coupled with better service delivery. Large volumes can be delivered within short span of time thereby adhering to strict deadlines with the help of best in class infrastructure and quality & trained workforce.

Key Characteristics of Everlast FRP Pultruded Sections:

• Maximum Corrosion Resistance: Responsible for enhancing the life of the product in harsh environments subject to extreme conditions of industries.

• High Strength and Light Weight: This property of FRP allows dependable support to applied loads providing higher strength to weight ratio as compared to any other material.

• Thermal & Electrical Non-Conductivity: Very essential characteristics ensuring highest safety standards for the personnel working there.

• Dimensional Stability: The product is so designed which maintains cross-section of shapes based on low co-efficient of thermal expansion.

• Electromagnetic transparency: The products does not interfere with the transmission of radio and microwave frequencies.

Process

Pultrusion is a continuous process for manufacture of composite materials with constant cross-section. Reinforced fibers are pulled through a resin, possibly followed by a separate preforming system, and into a heated die, where the resin undergoes polymerization. Many resin types may be used in pultrusion including polyester, polyurethane, vinyl ester and epoxy.

Diagram of the pultrusion process

1 - Continuous roll of reinforced fibers/woven fiber mat

2 - Tension roller

3 - Resin bath

4 - Resin soaked fiber

5 - Die and heat source

6 - Pull mechanism

7 - Finished hardened fiber reinforced polymer

We are one of the most advanced Pultruders in the industry as far as our technology & quality is concerned. We offer end –to-end services involving consulting, designing, production & assembly of custom designed pultruded products for a wide range of applications.

Comparison

| Sr. | PROPERTIES | EVERLAST | STEEL |

|---|---|---|---|

| 1 | Corrosion Resistance | Very High Resistance | Subject to Oxidation and Corrosion |

| 2 | Weight | Light Weight – Weighs only 25% as much as steel | Will require lifting equipment to move and place. |

| 3 | Conductivity | Low Conductivity and high dielectric properties | Conducts electricity. Potential shock hazard |

| 4 | Strength | Higher Strength to weight ratio than steel | Much lower strength to weight ratio |

| 5 | Stiffness | Will not permanently deform under load conditions | Any deformation will be permanent in nature |

| 6 | Impact Resistance | Glass mat in Everlast Sections distributes load evenly to prevent surface damage | Can permanently deform under impact |

| 7 | EMI / RFI Transparency | Transparent to Emi/RFI transmissions | Can interfere with EMI/RFI transmissions |

| 8 | Versatility | Pigments added to resin provide color throughout the part. Special colors available | Must be painted for color. To maintain color & corrosion resistance repainting may be required. |

| 9 | Field Fabrication | Can be field fabricated using simple carpenter tools with carbide or diamond tip blades. Lightweight for easier erection and installation. | Often required welding and cutting torches. Heavier material required special handling equipment to erect and install. |

| 10 | Cost | Lower installation & maintenance costs in industrial applications often equals lower life cycle costs. | Very High life cycle costs. |

Standard Profiles

| Profile | A | B | T | Wt / RMT |

|---|---|---|---|---|

| Square Tube | ||||

| 25 | 25 | 3 | 0.5 |

| 30 | 30 | 3 | 0.6 | |

| 40 | 40 | 3 | 0.8 | |

| 40 | 40 | 5 | 1.3 | |

| 50 | 50 | 3 | 1 | |

| 50 | 50 | 5 | 1.6 | |

| L - Angle | ||||

| 50 | 50 | 5 | 0.9 |

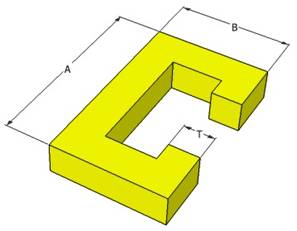

| C- Type | ||||

| 200 | 50 | 5 | 2.6 |

| 100 | 50 | 5 | 1.7 | |

| 75 | 30 | 3 | 0.7 | |

| 75 | 30 | 5 | 1.2 | |

| I Beam | ||||

| 100 | 100 | 6 | 3.1 |

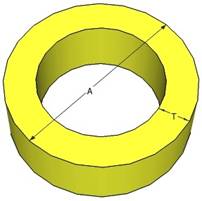

| Circular Pipe | ||||

| 50 | 3 | 0.9 | |

| 50 | 5 | 1.3 | ||

| 25 | 3 | 0.4 | ||

| 38 | 3 | 0.6 | ||

| 16 | 3 | 0.2 | ||

| Closed C-Type | ||||

| 84 | 24 | 4 | 1.1 |

Features

| FEATURES | DESCRIPTION | BENEFITS | APPLICATIONS |

|---|---|---|---|

| Strong | Unit strength in tension & compression in approx 20x that of steel when these propoerties are combined on the basis of unit density | Optional strength as desired. Exceptionally high impact strength reduces damage potential | Structural Process equipment support. Tank Supports, Cooling tower ancillaries. Flooring supports. Trusses & Joints |

| Light weight | Density of pultruded components is about 20% of steel and 60% of aluminium. | Higher performance at less weight. Lower shipping handling & installation costs. Less operational energy demand | Automative lead springs & bumpers. Prefabricated walkways & Platforms. Bus components |

| Corrosion Resistance | Unaffected by exposure of a great variety of corrosive enviornment & chemicals | Minimum maintenance costs. Long tern safety. Longer Life | Chemical plant hand railings gratings, walkways & bridges cable trays, pipe supports |

| Electrical Insulation | Provides strength and rigidity with dielectric propoerties | Lesser no. of components. Non-magnetic & safe. Predictable insulation values for wide range of frequencies. | Ladders, cable trays. Switch gear components. Mounting braces and backboards. |

| Termal Insulation | Pultruded Components have a low thermal conductivity, 1/250 of aluminium & 1/60 of steel. | Reduces installation thickness Elimates condensation problems. Reduces energy operation requirements. | Bulk head frames. Walk in refrigerator door jams. Window frames. Insulated roll up panel doors |

| Consolidation | Many individual components can be combined into a larger structure | Reduced assembly cost, reduced inventory. Fewer parts improve reliability. | Window latch supports. Roll up door |

| Dimensional Stability | Pultruded components are highly resistant to warping stretch/swelling over a wide range of temperature & stresses | No permanent deformation under high stress. Close tolerances. | Spring bumpers. Crossing gate arms, scrubber components |

| Safety | The pultruded components are very strong & safe to work with. They are microbes and insect proof. | Many gratings suffer from the problem of microbes etc. due to wet or unhygienic working conditions. | Chemical & pharmaceutical industries |

Application

Pultrusion products have a wide range of applications spanning across industries like infrastructure, elecrical, pharmaceutical, food & beverage, heavy industries, Automotive etc. We have developmed several applications using pultruded products in several of these industries. These applications are listed below. Along with this we also work closely with our clients to develop customizes products to suite their application. For more information on our current applications or other application kindly get in touch with us directly.

| CURRENTLY DEVELOPED APPLICATIONS | |

|---|---|

| • Walkways & Bridges • Electrical Insulating Sections • Cooling Tower Sections • Cable Tray Systems • Maintenance Platforms • Ladders and Hand Rails • Fencing & Signboards • Buildings and Sheds |

• Mezzanines • Booths • Baying Platforms • Pipe and Equipment Racks • Tank Loading Platforms • Trash and Bar Screens • Decks • Tank Covers and Supports |